Standardised procedure safeguards the savings potential in the industry

A comprehensive analysis of the ACTUAL situation of all relevant fields of action related to energy is followed in a second step by the development of a broad roadmap for the long-term, strategic positioning of your company.

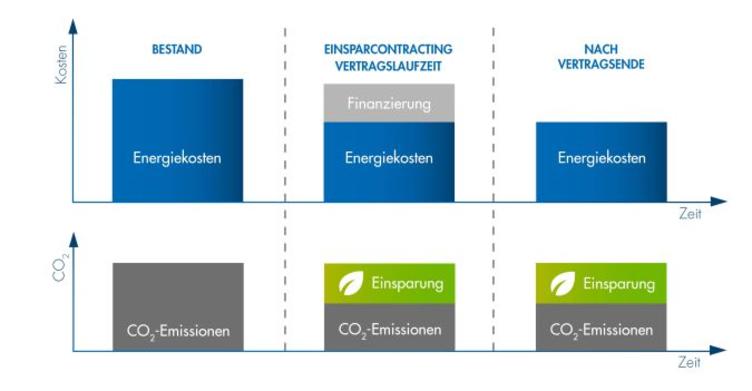

The examination is carried out from the inside out. The analysis of the energy requirements is followed by the assessment of the energy generation and finally the review of the energy acquisition rules. The specifics of the project sequence are coordinated with the customer. After determining the suitable system components, the savings potentials are estimated by means of a preliminary study. A detailed study is conducted to define these estimated savings potentials in more detail, to determine the appropriate procedures and to calculate the economic viability. Upon completion of the guaranteed energy savings contract, the procedures are implemented in accordance with the economic viability or the degree of production improvement. As soon as the procedures have been implemented, the contractually guaranteed savings start to take effect. In the context of quality control, continuous reporting and regular optimisation with regard to the resource-efficient operation of your production will take place.

|

Environmental benefit |

Customer benefit | |

|---|---|---|

|

|

GETEC heat transformation is a particularly innovative project in the field of efficiency improvement. It involves the transformation of lost waste heat from a lower temperature level into useful heat with a higher value by means of a special process. No additional primary energy is used for this procedure. Exclusively the energy content of the lost heat is used, and part of it returned to the production processes in the form of useful heat. These kinds of innovative solutions will be part of future energy supply concepts in times of the move toward renewable energies, where the main task is to reduce CO2 in the industry and customers have a vested interest in keeping the value of spent resources within the company as efficiently as possible.

We embody partnership –

find your contact.

With more than 70 locations throughout Europe, we are always at your doorstep.

Contact us. We are here for you.